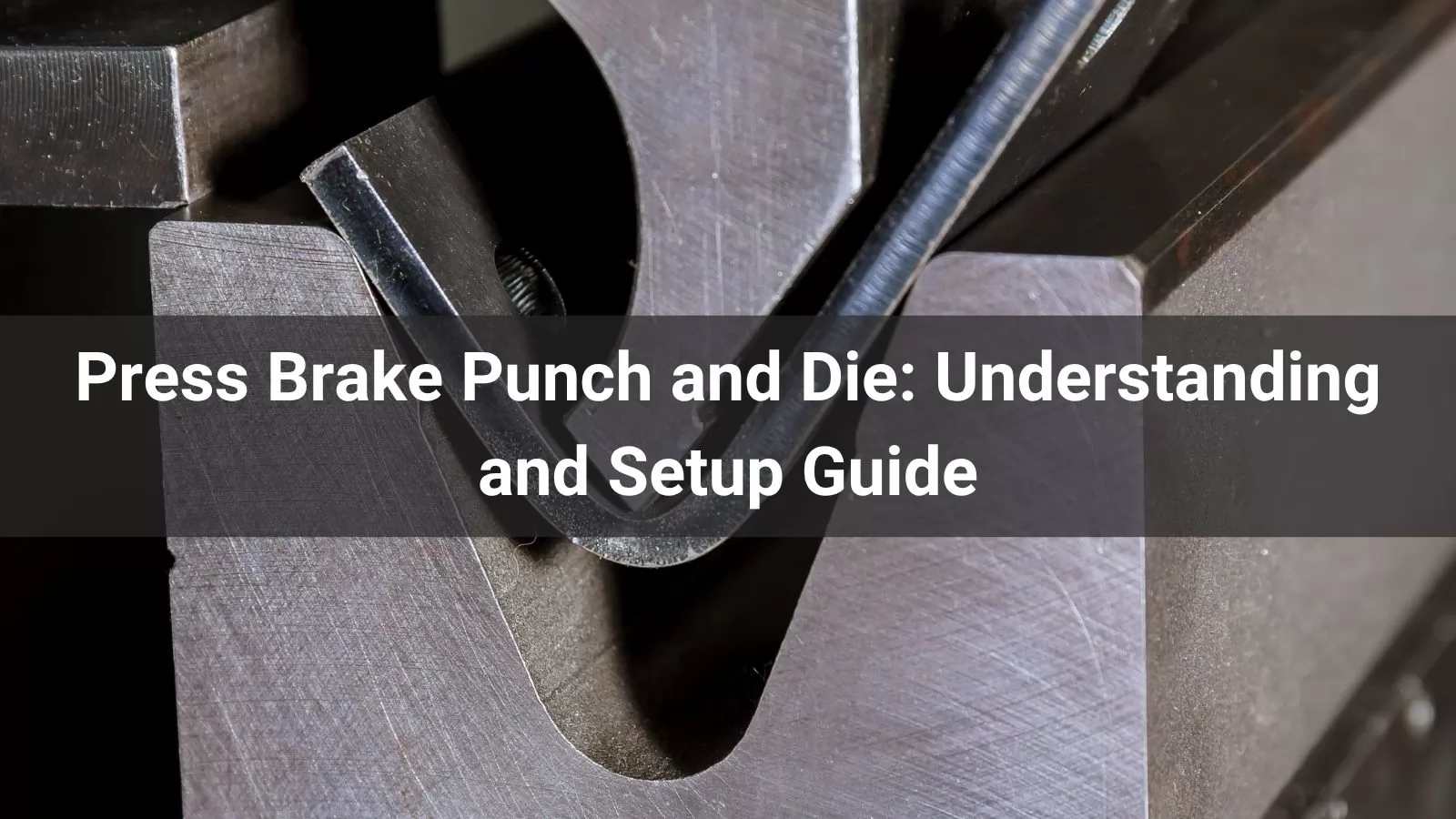

Press brake punch and die systems are essential for shaping sheet metal with precision in fabrication processes. The punch, attached to the upper ram, presses the material into the die, which is mounted on the lower bed, to create the desired bend. This guide covers their functionality, selection, setup, and maintenance to ensure optimal performance.

A press brake punch and die work together to bend sheet metal into specific shapes. The punch, the upper tool, applies force to the material, while the die, the lower tool, supports it and defines the bend’s angle and radius. These tools are used in various press brake types, such as mechanical, hydraulic, CNC, and hybrid models, each tailored to different applications. For more details on press brake types, refer to our comprehensive guide.

Choosing the appropriate punch and die is critical for accurate and efficient bending. The material’s thickness, tensile strength, and ductility influence the tooling choice, as thicker or harder materials demand robust tools with higher tonnage capacity. The desired bend angle determines the punch tip and die opening, with acute angles requiring sharper punches and obtuse angles needing wider dies. Additionally, the bend radius affects the punch’s tip radius; smaller radii need tighter tips to prevent material cracking, while larger radii require broader tips. Tooling must also be compatible with the press brake’s clamping system and tonnage limits, and for high-volume production, durable, wear-resistant materials like carbide are preferred.

Punches and dies are typically made from hardened tool steel, such as D2 or A2, or carbide, valued for their durability, wear resistance, and ability to handle high-pressure bending. Advanced tools may feature coatings like titanium nitride to reduce friction and extend lifespan. The material choice depends on the application, with carbide being ideal for high-volume production or abrasive materials.

Proper setup is vital for precision, safety, and tool longevity. Begin by cleaning the punch, die, and press brake bed to remove debris that could affect the workpiece’s surface. Next, align the punch and die carefully to ensure even bending and avoid tool damage, using alignment gauges if needed. Secure the tools with the press brake’s clamping system, such as Promecam or WILA, and verify they are firmly fastened. Adjust the press brake’s tonnage to match the material and bend requirements, as excessive force can harm tools or material. Perform test bends on scrap material to confirm accuracy and fine-tune settings. Finally, conduct safety checks, inspecting for loose components and ensuring guards and operator protocols are in place.

Punches come in various shapes for different bending tasks. The standard punch, with a thick body and narrow tip, is ideal for bending thicker materials due to its high tonnage capacity. Acute angle punches, designed for bends of 30° or less, feature a sharp tip for precision and can handle larger angles up to 60°. Gooseneck or swan neck punches have a curved design, enabling deep or complex bends like U-shaped profiles without workpiece interference. Radius punches, with rounded tips, create smooth, U-shaped bends, often paired with matching dies for rounded corners. Narrow punches, with a thin profile, fit tight spaces and are perfect for closing box profiles or intricate bends.

Punch specifications include the product code, a manufacturer’s identifier with dimensional details; the tip radius, which determines the bend radius and is larger for thicker materials; the angle, ranging from 30° for needle punches to 90° for coining; the height, where taller punches support deeper bends like box forming; and the load capacity, the maximum force the punch can withstand without deforming.

Dies support the material and shape the bend. Single V dies, with a single V-shaped cavity, are the most versatile, with an optimal V-opening of 6–8 times the material thickness. Multi V dies feature multiple V-openings, allowing different thicknesses or angles without tool changes. Channel forming dies create U-shaped channels in one pass, more efficient than traditional V dies. Hemming dies flatten acute bends for folded edges, available in sprung-loaded or U-section designs. Corrugating dies produce textured, corrugated patterns for specialized applications.

Die specifications include the V-opening angle, typically 30° to 90°, which affects the maximum bend angle; the radius of the V’s rounded corners, influencing bend quality; and the product code, a unique identifier for cataloging.

Regular maintenance ensures tool longevity and consistent performance. Clean tools after each use to remove oil, debris, and metal particles. Inspect punches and dies for wear, cracks, or chipping, particularly on tips and edges. Apply appropriate lubricants to reduce friction during operation. Store tools in a dry, organized rack to prevent rust or damage. Regrind worn tools to restore precision, but avoid removing excessive material. For detailed maintenance tips, download our press brake tooling care guide.

Clamping systems secure punches and dies to the press brake. Promecam, or European-style, clamps are common for manual or semi-automatic setups, while WILA systems offer hydraulic or pneumatic clamping for faster tool changes. Manual clamps are cost-effective but slower, while automated clamping suits high-volume production. For setup optimization tips, see our guide.

Automatic tool changers store punches and dies and swap them as needed, significantly reducing setup time. These systems are ideal for high-mix, low-volume production. Learn more in our tool changer overview.

Press brake punches and dies are crucial for precise sheet metal bending. By understanding their types, selecting appropriate tools, and following proper setup and maintenance practices, manufacturers can enhance efficiency and quality. Advanced clamping and automated storage systems further boost productivity. Explore our guides on press brake types, tooling maintenance, and automation for more insights.

Fastest

Installation

Top-Notch

Equipment

24/7 Customer

Support

100% Secured

Payment