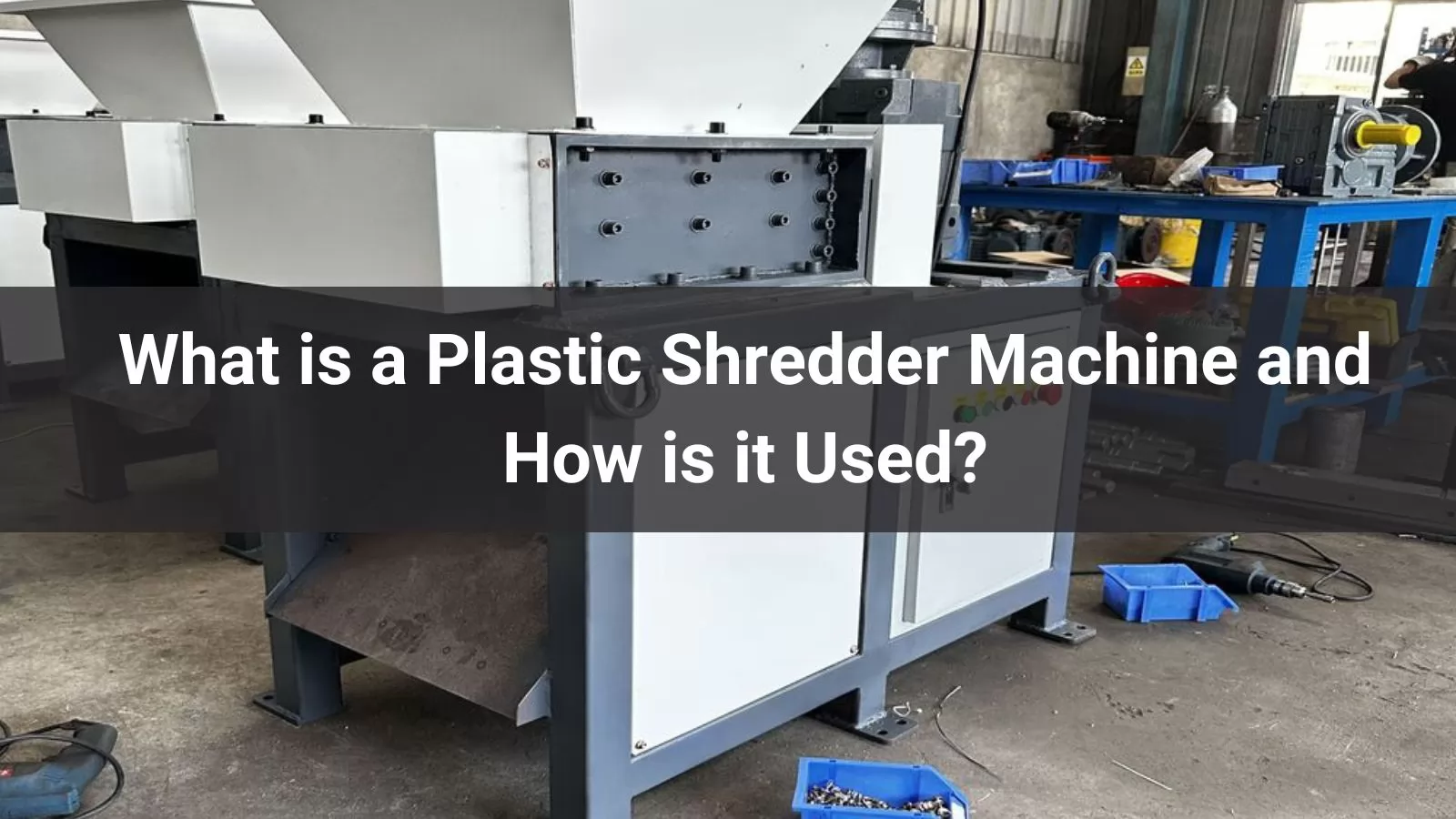

As someone curious about recycling and waste management, I’ve often wondered how we can effectively tackle the growing problem of plastic waste. One machine that plays a critical role in this process is the plastic shredder machine. In this article, I’ll share what I’ve learned about what a plastic shredder machine is, how it works, and why it’s so important in today’s world.

A plastic shredder machine is a powerful piece of equipment designed to break down plastic materials into smaller, more manageable pieces. I first encountered one while researching recycling solutions, and I was amazed by its ability to transform bulky plastic items—like bottles, containers, or even industrial plastic waste—into tiny fragments. These machines come in various sizes, from small units for home or community use to massive industrial shredders capable of processing tons of plastic per hour.

The core idea behind a shredder is simple: it uses sharp, rotating blades or cutters to tear apart plastic. But when I looked deeper, I found that these machines are engineered with precision. They often feature robust motors, durable blades made of hardened steel, and sometimes even multiple stages of shredding to ensure the plastic is reduced to the desired size. Some shredders are designed for specific types of plastic, like PET (used in water bottles) or HDPE (used in milk jugs), while others are versatile enough to handle mixed plastics.

When I explored how these machines are used, I discovered they’re a cornerstone of the recycling process. Here’s a step-by-step look at how I’d use a plastic shredder machine, based on what I’ve learned:

Preparation: First, I’d collect the plastic waste, ensuring it’s clean and free of contaminants like food residue or non-plastic materials. Many recycling facilities sort plastics by type to improve efficiency, so I might need to separate PET from PP or HDPE.

Feeding the Machine: Next, I’d feed the plastic into the shredder’s hopper, a large funnel-like opening. Some machines have conveyor belts for continuous feeding, which I found especially common in industrial settings. Smaller machines might require manual loading, which I’d do carefully to avoid jams.

Shredding Process: Once the plastic enters the machine, the blades take over. I was fascinated to learn that shredders can be single-shaft, double-shaft, or even quad-shaft, depending on the level of shredding needed. The blades rotate at high speeds, slicing the plastic into small flakes or granules. Some machines even have screens to control the size of the output.

Collecting the Output: After shredding, the plastic pieces are collected in a container or bag. I found that these shredded plastics, often called “plastic flakes,” are easier to transport and process further. They might go on to be melted and reformed into new products, like plastic pellets for manufacturing.

Maintenance: From what I’ve read, keeping the shredder in top shape is crucial. I’d regularly check the blades for wear, clean out any plastic residue, and ensure the motor is running smoothly. Industrial shredders often have automated maintenance alerts, which I think is a great feature.

As I dug deeper, I realized plastic shredders are vital for several reasons. First, they make recycling more efficient by reducing the volume of plastic waste, which saves space and lowers transportation costs. Second, shredded plastic is easier to process into new products, supporting a circular economy. I was surprised to learn that shredded plastic can be used to make everything from new bottles to clothing fibers and even construction materials.

Moreover, plastic shredders help address the environmental crisis. Plastic waste is a massive problem—when I checked recent data, I found that over 300 million tons of plastic are produced annually, much of it ending up in landfills or oceans. By shredding plastic, we can divert it from these harmful destinations and give it a second life.

Learning about plastic shredder machines has opened my eyes to the mechanics of recycling. Whether it’s a small shredder for a community project or a heavy-duty machine in a recycling plant, these devices are unsung heroes in the fight against plastic waste. If I were to use one myself, I’d feel empowered knowing I’m contributing to a cleaner planet. If you’re as intrigued as I am, I encourage you to explore local recycling programs or even small-scale shredders for DIY projects—together, we can make a difference!

Fastest

Installation

Top-Notch

Equipment

24/7 Customer

Support

100% Secured

Payment